In the present consistently developing commercial center, signs are something beyond pointers or directional aides; they are a strong type of correspondence that spans organizations with their likely clients. Sign assembling, a basic section of the visual correspondence industry, incorporates a great many cycles, innovations, and materials. This article dives into the complexities of sign assembling, investigating its importance, the different sorts of signs, creation processes, materials utilized, innovative headways, and manageability rehearses.

The Meaning of Sign Assembling

Signs act as a quiet yet powerful promoting device, giving an initial feeling that can either draw in or prevent possible clients. They are a fundamental part of a business’ marking system, assisting with passing on the organization’s message, values, and impressive skill. Powerful signage can upgrade brand perceivability, advance items or administrations, and work with wayfinding. In this unique situation, sign assembling assumes a crucial part in changing reasonable plans into substantial resources that catch consideration and convey goal.

Kinds of Signs

The range of sign assembling is expansive, enveloping various items each fit to explicit purposes and conditions:

Open air Signs: These incorporate customer facing facade signs, announcements, wayfinding signs, and advanced shows, intended to endure climate components while boosting perceivability.

Indoor Signs: Containing enlightening and directional signage, indoor signs likewise incorporate limited time shows and enriching components inside a business setting.

Advanced Signage: This quickly developing area incorporates Drove and LCD show signs which are adaptable in refreshing substance and drawing in watchers with dynamic visuals.

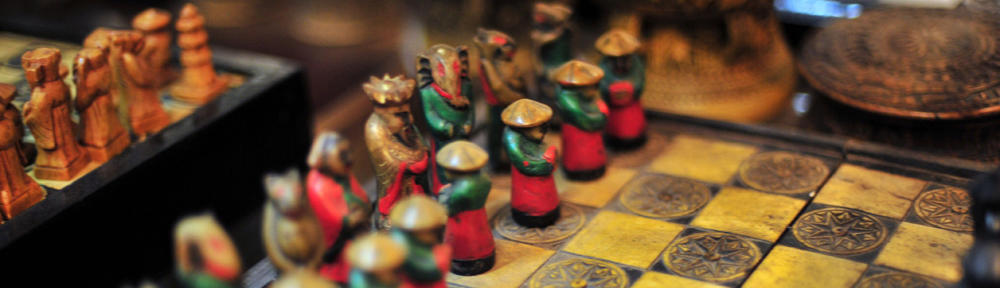

Neon Signs: Known for their energetic, retro allure, neon signs are encountering a resurgence, mixing conventional Sign Manufacturing craftsmanship with contemporary plan.

Creation Cycles

The assembling of signs includes a blend of customary craftsmanship and current innovation:

Plan: This underlying stage incorporates conceptualization and visual computerization, where the visual components and particulars of the sign are concluded.

Material Determination: Contingent upon the plan, different materials like metal, plastic, wood, or glass are picked for their sturdiness, feel, and cost-viability.

Manufacture: Procedures range from cutting, welding, and trim to computerized printing and CNC directing, molding the materials into the last sign construction.

Gathering: Parts like lighting installations (for enlightened signs) are introduced, and the sign is collected, it are safely coordinated to guarantee all components.

Wrapping up: Incorporates painting, covering, or applying computerized illustrations to the sign, trailed by quality checks to guarantee sturdiness and lucidness.

Establishment: The last step includes mounting or introducing the sign at its assigned area, expecting ability to guarantee wellbeing and perceivability.

Materials and Advances

Development in materials and advances has extraordinarily extended the potential outcomes in sign assembling:

Eco-accommodating Materials: With a rising accentuation on manageability, makers are utilizing recyclable materials and energy-productive LEDs.

Computerized Printing: Top notch computerized printers consider energetic, complex illustrations on various substrates.

CNC Steering and Laser Cutting: These advancements empower exact cuts and mind boggling plans, taking into consideration custom shapes and fine subtleties.

Savvy Signs: Consolidating QR codes or NFC innovation, shrewd signs connect with cell phones, offering a computerized aspect to actual signage.

The Future and Manageability

The fate of sign assembling lies in the mix of creative advances and maintainability rehearses. Increased reality (AR) and intuitive computerized signage are set to offer vivid encounters, while the business’ center is moving towards diminishing natural effect through manageable materials